One of the greatest challenges facing the extraction of bitumen from Alberta’s oil sands is dealing with the massive quantities of waste products generated in the extraction process. The waste generated, known as tailings sludge, is composed of silica and clay particles, water, ions, residual bitumen and trace organic species. Currently, typical waste treatment involves addition of a chemical additive followed by disposal into large tailing ponds. The chemical additive causes the fine silica and clay particles to aggregate. These aggregations then settle during deposition into the tailing ponds, and a dewatering step must occur before the solid waste can be used as a foundation for soil deposits and reforestation. This dewatering step is critical in the waste treatment process, and remains a challenge largely due to the enormous volume of existing tailings waste. New chemical agents or physical methods of dewatering are needed for optimal dewatering of tailing ponds. But first, we need to take a step back and ask: What are the molecular characteristics of the surfaces of these particles in contact with water? More specifically, can we find spectroscopic methods that can probe then dewatering process? If so, then we assess which additives are the most promising for dewatering and determine their mechanism of action.

One of the greatest challenges facing the extraction of bitumen from Alberta’s oil sands is dealing with the massive quantities of waste products generated in the extraction process. The waste generated, known as tailings sludge, is composed of silica and clay particles, water, ions, residual bitumen and trace organic species. Currently, typical waste treatment involves addition of a chemical additive followed by disposal into large tailing ponds. The chemical additive causes the fine silica and clay particles to aggregate. These aggregations then settle during deposition into the tailing ponds, and a dewatering step must occur before the solid waste can be used as a foundation for soil deposits and reforestation. This dewatering step is critical in the waste treatment process, and remains a challenge largely due to the enormous volume of existing tailings waste. New chemical agents or physical methods of dewatering are needed for optimal dewatering of tailing ponds. But first, we need to take a step back and ask: What are the molecular characteristics of the surfaces of these particles in contact with water? More specifically, can we find spectroscopic methods that can probe then dewatering process? If so, then we assess which additives are the most promising for dewatering and determine their mechanism of action.

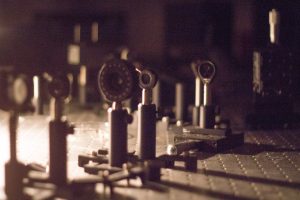

In the Gibbs lab we use nonlinear optics (NLO) to study the structure and order of water at the silica surface. Using NLO methods we can determine the effects of different ionic species on water structure at the silica/aqueous interface, which could have direct implications in the dewatering of silica in tailings sludge. For more information, please visit Nonlinear Optics.